electric scooter wiring diagram owner’s manual

Welcome to the Electric Scooter Wiring Diagram Owner’s Manual! This guide provides essential information for understanding, installing, and maintaining your scooter’s electrical system safely and efficiently.

Purpose and Scope of the Manual

This manual is designed to guide users through the safe and effective use of their electric scooter’s wiring diagram. It covers installation, operation, and maintenance, ensuring optimal performance and longevity. The scope includes step-by-step instructions, safety precautions, and troubleshooting tips to help users understand and manage their scooter’s electrical system. By following this manual, users can ensure compliance with safety standards and maintain their scooter’s functionality over time.

Importance of Understanding the Wiring Diagram

Understanding the wiring diagram is crucial for the safe and efficient operation of your electric scooter. It helps identify components, troubleshoot issues, and perform repairs correctly. Proper knowledge prevents electrical hazards and ensures compliance with safety standards. By grasping the diagram, users can maintain their scooter’s performance, avoid costly damages, and extend its lifespan. This knowledge is essential for both beginners and experienced users aiming to optimize their scooter’s functionality and reliability over time.

Safety Precautions and Guidelines

Always disconnect the battery before working on wiring to prevent electrical shocks. Wear protective gear and follow safety guidelines to avoid hazards and ensure proper system functionality.

General Safety Tips for Handling Electrical Components

When working with electrical components, always disconnect the battery first to avoid shocks. Use insulated tools and wear protective gloves and eyewear. Ensure the scooter is on a stable surface and avoid moisture. Never touch live wires or components with bare hands. Keep loose clothing tied back and avoid jewelry that could conduct electricity. Work in a well-lit, dry environment and follow proper grounding procedures. Always refer to the wiring diagram for accurate connections and never bypass safety features; Proper preparation prevents accidents and ensures safe repairs.

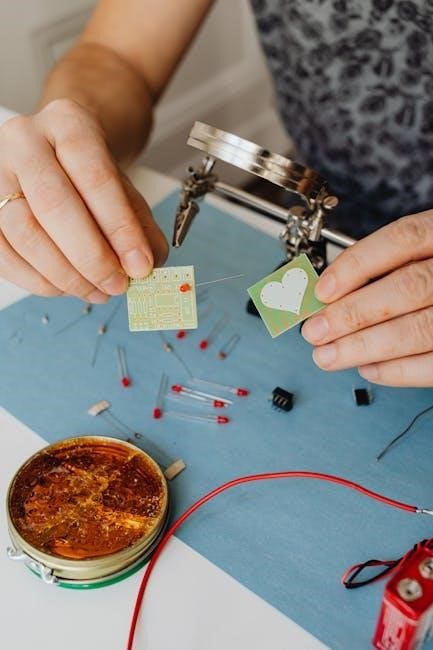

Protective Gear and Tools Required

Essential protective gear includes insulated gloves, safety goggles, and a well-fitting apron. Tools needed are a multimeter, screwdrivers, pliers, and a wire stripper. A clean, dry workspace with good lighting is crucial. Ensure all tools are properly insulated to prevent electrical shocks. Use a workbench with a non-conductive surface for added safety. Regularly inspect tools for damage and keep loose clothing secured. Always refer to the wiring diagram for precise connections and avoid using damaged or inappropriate tools to prevent system damage or personal injury.

Precautions Before Starting Any Wiring Work

Always ensure the scooter is powered off and the battery is disconnected before starting any wiring work. Verify the wiring diagram matches your scooter’s electrical system. Ground the scooter to prevent static electricity damage. Secure loose clothing and long hair to avoid entanglement with tools or wires. Use non-conductive tools to prevent electrical shocks. Keep the workspace clean, dry, and well-lit. Double-check all connections before reconnecting the battery. Never attempt complex modifications without proper experience or guidance to ensure safety and system integrity.

Understanding the Electric Scooter Wiring Diagram

This section explains the purpose and visual representation of the wiring diagram, detailing how it guides repairs, customizations, and electrical system understanding for safe modifications.

Key Components of the Wiring Diagram

The wiring diagram typically includes the battery, motor, controller, throttle, and sensors. It visually represents connections, such as wires, circuits, and fuses, essential for understanding the scooter’s electrical system. Each component is labeled with symbols or codes, ensuring clarity for repairs, maintenance, or upgrades. The diagram also shows how power flows from the battery to the motor via the controller, highlighting critical safety features like circuit breakers and grounding points to prevent electrical hazards.

Symbols and Notations Used in the Diagram

The wiring diagram uses standardized symbols to represent components like batteries, motors, and controllers. Lines denote wires, while color coding indicates polarity—red for positive and black for negative. Abbreviations like “VCC” (voltage supply) and “GND” (ground) are common. Symbols for fuses, switches, and connectors are also included to simplify tracing connections. These notations ensure clarity, helping users identify and understand each part of the electrical system quickly and accurately.

Interpreting the Wiring Layout

Interpreting the wiring layout involves understanding how components connect and function together. Start by identifying the main power source, typically the battery, and trace connections to the motor, controller, and other accessories. Follow the diagram to ensure proper routing and connections. Pay attention to color-coded wires, which indicate positive and negative terminals. Always verify connections against the diagram to avoid short circuits or malfunctions. This step ensures a safe and functional electrical system for your electric scooter.

Step-by-Step Installation Guide

Start by preparing the scooter, then connect the battery and motor. Install the controller and throttle, ensuring secure connections. Finally, test all components to confirm functionality.

Preparing the Scooter for Wiring

Begin by disconnecting the battery to ensure safety. Remove the seat and any panels to access the wiring harness. Gather tools like screwdrivers, pliers, and wire strippers. Inspect existing wires for damage or wear. Clean the area around the wiring compartment to prevent dust interference. Label wires if necessary for easy identification. Ensure all components are securely fastened before proceeding. Double-check that the scooter is turned off and all power sources are disconnected to avoid accidental start-ups during wiring work.

Connecting the Battery and Motor

Start by locating the battery terminals and motor connector. Attach the positive (red) and negative (black) wires to the motor, ensuring proper polarity. Secure the connections tightly using screws or clips. Double-check for sparks or short circuits before proceeding. Use heavy-duty cables to handle high current flow. Once connected, test the motor at low power to confirm functionality. Always refer to the wiring diagram for correct polarity to avoid damage. After verifying, ensure all connections are insulated and secure.

Installing the Controller and Throttle

Begin by mounting the controller in a dry, protected area near the battery. Connect the controller to the motor using the appropriate wires, ensuring secure fastening. Attach the throttle to the handlebar and link it to the controller, matching the wire colors to their respective functions. Reconnect the battery and test the system by gently squeezing the throttle to check motor response. Ensure all connections are insulated and secure, and consider adding fuses for protection. For optimal performance, configure any programmable settings on the controller and test the scooter at low speed before full operation.

Troubleshooting Common Electrical Issues

Troubleshoot electrical issues by checking for loose connections, damaged wires, or blown fuses. Use a multimeter to test battery voltage and motor resistance. Identify faulty components and repair or replace them as needed to restore function.

Identifying Faults in the Wiring System

Identify wiring faults by inspecting for loose connections, frayed wires, or corrosion. Use a multimeter to test voltage and resistance across components. Check for blown fuses or tripped circuit breakers. Look for signs of overheating, such as melted insulation or burn marks. Verify the wiring diagram to ensure connections match the schematic. Test each circuit systematically to pinpoint faults. Consult the manual for specific troubleshooting steps if issues persist.

Diagnosing Power Supply Problems

Diagnose power supply issues by checking the battery voltage and charger output. Use a multimeter to test for continuity and voltage drop across connections. Inspect the wiring diagram to trace power lines and ensure all components are properly connected. Look for blown fuses or faulty relays. Verify the battery terminals are clean and secure. Test the charger’s output to confirm it matches the scooter’s requirements. Consult the manual for specific troubleshooting steps to resolve power-related faults effectively.

Repairing or Replacing Damaged Wires

Begin by inspecting the wiring diagram to identify the damaged circuit. Carefully cut the faulty wire near the connector or junction. Strip the insulation at the cut ends and splice or solder the wires securely. Use heat-shrink tubing or electrical tape to protect the repair. Ensure all connections are tight and insulated. Test the circuit with a multimeter to confirm continuity and proper voltage. If damage is extensive, replace the entire wire, following the diagram for correct routing and connections.

Maintenance and Upkeep of the Wiring System

Regularly inspect connections, clean corrosion, and ensure wires are secure. Protect the system from moisture and extreme temperatures. Refer to the wiring diagram for specific maintenance procedures.

Regular Inspections and Checks

Perform monthly inspections of the wiring system to ensure all connections are secure and free from damage. Check for frayed wires, loose terminals, and signs of corrosion. Refer to the wiring diagram to verify proper connections and routing. Clean any dirt or debris that may interfere with electrical flow. Test the system under load to identify potential issues early. Address any discrepancies immediately to prevent electrical failures. Regular maintenance ensures reliability, safety, and optimal performance of your electric scooter.

Cleaning and Protecting the Wiring

Regularly clean the wiring system to prevent dirt and moisture buildup. Use a soft-bristle brush or compressed air to gently remove debris. Avoid harsh chemicals, as they may damage insulation. Apply a silicone-based protective spray to shield wires from corrosion and environmental factors. Inspect wiring harnesses for signs of wear and secure them with heat-resistant tubing in high-temperature areas. Protect connectors with dielectric grease to prevent corrosion. Proper cleaning and protection ensure long-term reliability and safety of the electrical system.

Upgrading or Modifying the Wiring Diagram

When upgrading or modifying the wiring diagram, plan carefully to ensure compatibility with existing components. Use high-quality wires and connectors to maintain reliability. Consult the manual or a professional to avoid system malfunctions. Test modifications thoroughly before final installation. Document changes for future reference and ensure compliance with safety standards. Upgrades should enhance performance without compromising safety or functionality. Always follow proper electrical practices to prevent damage or hazards.

Advanced Customizations and Modifications

Explore advanced customizations to enhance performance, such as upgrading electrical components or adding accessories. Modifications require careful planning to ensure compatibility and safety. Always follow proper wiring practices to avoid system malfunctions and maintain reliability. Consult the manual or a professional for guidance. Document all changes for future reference and ensure compliance with safety standards. Upgrades should enhance functionality without compromising safety or performance.

Adding Accessories to the Wiring System

Adding accessories like lights, horns, or Bluetooth connectivity can enhance your scooter’s functionality. Always ensure compatibility with your scooter’s wiring system. Consult the manual for guidance on safe installation practices. Use high-quality connectors to prevent electrical issues. Avoid overloading the circuit to maintain system stability. Test accessories before permanent installation. Consider professional assistance for complex additions. Document all modifications for future reference. Ensure safety by powering off the scooter during installation. Use protective gear to prevent electrical shocks or injuries. Upgrading thoughtfully improves performance and user experience. Compliance with safety standards is crucial for reliability and longevity.

Upgrading the Electrical Components

Upgrading electrical components like the motor, controller, or battery enhances performance and efficiency. Always consult the wiring diagram to ensure compatibility. Choose components with higher power ratings to improve speed and torque. Disconnect the battery before starting work. Follow the diagram to reconnect wires safely. Test the system after installation to ensure proper functionality. Document changes for future reference. Avoid overloading the system, as it may cause electrical failures. Upgrades should align with the scooter’s design specifications for optimal results and safety.

Customizing the Throttle and Speed Settings

Customizing the throttle and speed settings allows for personalized performance. Refer to the wiring diagram to locate the throttle potentiometer and speed controller. Adjust the throttle’s sensitivity by modifying its resistance or upgrading to a Hall-effect throttle for smoother control. Update the controller’s firmware or adjust its settings to limit or increase top speed. Ensure all connections are secure after modifications. Test the scooter at low speeds to confirm proper functionality. Always follow safety guidelines to avoid electrical hazards or loss of control during customization.

Legal and Regulatory Considerations

Ensure compliance with local electrical standards and safety regulations. Verify scooter modifications meet legal requirements to avoid penalties. Check warranty terms for electrical component modifications.

Compliance with Local Electrical Standards

Ensure your electric scooter’s wiring complies with local electrical codes and regulations. Research regional standards for wire gauges, connectors, and safety features. Verify that all components meet certification requirements. Proper documentation and permits may be necessary. Non-compliance can result in legal penalties or safety hazards. Always consult local authorities or certified professionals to confirm adherence to electrical standards. This ensures your scooter operates safely and legally within your area.

Ensuring Safety Standards Are Met

Adhere to established safety standards when working with your electric scooter’s wiring. Use components certified by recognized organizations, such as UL or ETL, to ensure reliability and safety. Properly insulate all connections and avoid overloaded circuits. Regularly test the system for short circuits or voltage drops. Follow manufacturer guidelines for wire gauges and connections. Non-compliance can lead to electrical hazards or system failures. Always prioritize safety to protect both the rider and the scooter’s electrical system.

Warranty and Liability Information

Your electric scooter’s wiring diagram and components are covered under a limited warranty, typically spanning 6 to 12 months from purchase. This warranty covers manufacturing defects but excludes damage caused by misuse, neglect, or unauthorized modifications. The manufacturer is not liable for injuries or property damage resulting from improper wiring or failure to follow safety guidelines. Users are responsible for adhering to the manual’s instructions to maintain warranty validity and ensure safe operation.

Completing this manual ensures understanding of your scooter’s wiring system. Always perform final checks to confirm proper connections and functionality. Safe riding!

Final Testing of the Wiring System

After completing the wiring setup, perform a thorough test to ensure all components function correctly. Start by turning on the power at the lowest setting and gradually increase. Check the motor, brakes, lights, and throttle for proper operation. Verify there are no short circuits, flickering, or unusual heat. Test the scooter in a safe, open area to confirm smooth acceleration and braking. If any issues arise, refer to the troubleshooting section or consult a professional. Safety is paramount, so never test the scooter in traffic or risky conditions.

Ensuring Everything Functions Correctly

Once the wiring is complete, verify each component’s operation. Test the motor, brakes, lights, and throttle to ensure smooth functionality. Check for consistent power delivery and proper signal response. Inspect connections for tightness and integrity. Ensure no short circuits or loose wires exist. Validate that all safety features, such as brakes and cutoff switches, operate as intended. If any component malfunctions, consult the troubleshooting guide or seek professional assistance. Proper function ensures reliability, performance, and rider safety.

Long-Term Maintenance and Care

Regularly inspect the wiring for signs of wear, corrosion, or damage. Clean connectors to prevent rust and ensure secure connections. Apply a thin layer of dielectric grease to protect contacts from moisture. Store the scooter in a dry, cool place to avoid overheating or humidity damage. Avoid exposure to extreme temperatures or chemicals. Schedule professional inspections annually to identify and address potential issues early. Proper care extends the lifespan of electrical components, ensuring optimal performance and safety over time. Consistent maintenance prevents costly repairs and enhances reliability.